WAECO ASC 6400 G

Air conditioning service unit, triple certified, 30 kg

High-volume, fully automatic and world’s first triple certified A/C service unit – specially designed for buses, trains, helicopters and custom application. Thanks to a new modular concept, basic ASC can be turned to a service unit for either R134a, R1234yf or R513A refrigerants, depending on the appropriate connection kit, for one refrigerant type of your choice (sold separately).

…AND MORE

• Fully automatic A/C service – saves time in the workshop and prevents costly downtime

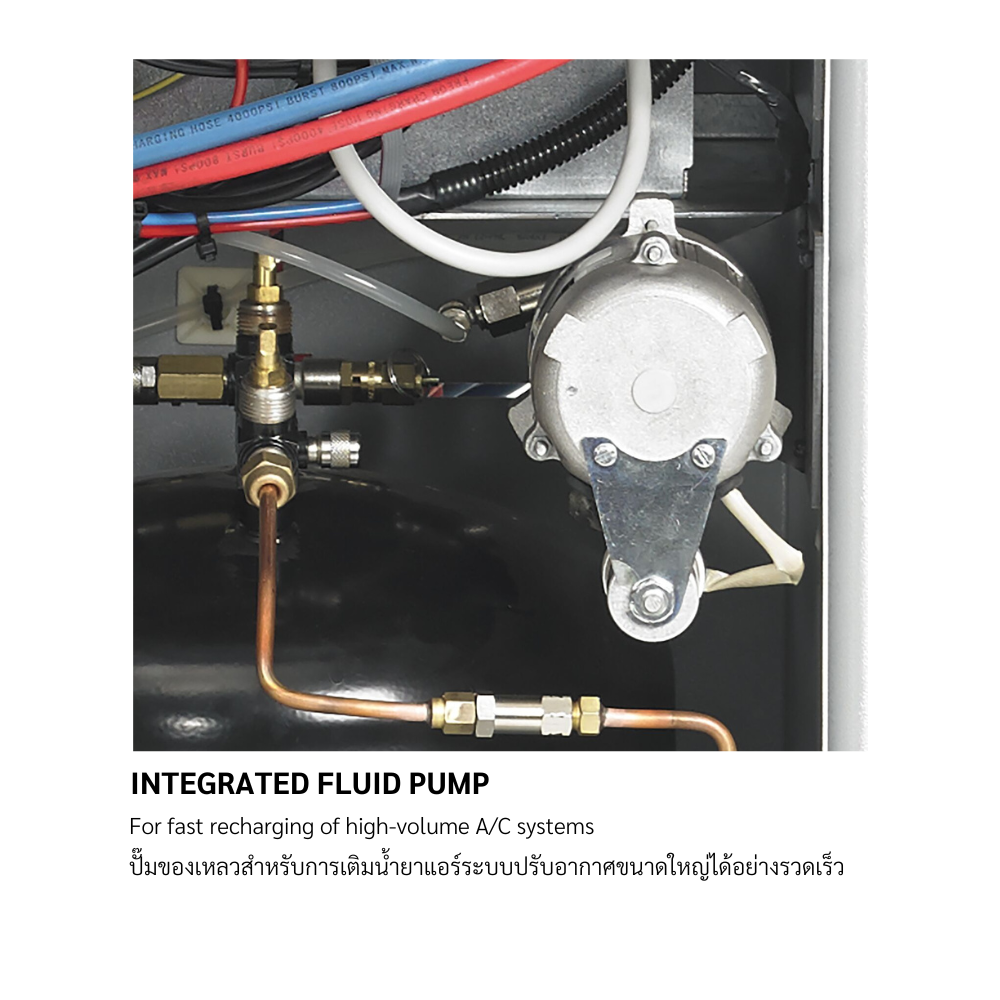

• Comes with high-capacity vacuum pump and additional fluid pump – designed for large vehicles

• Heated charging cylinder for high-speed charging – heat-up also possible during the charging process

• Optional heat belt for faster recycling saves up to 80 % work time during A/C service

• Heavy-duty design with 8-bearing weighing platform – no calibration needed

• Humidity-free storage and feeding system for fresh oil and UV additive supplied with the associated connection kit (sold separately)

• Approved by Deutsche Bahn, EvoBus, OMNIplus, Valeo

PROFESSIONAL A/C SERVICE ON BUSES AND TRAINS

Save valuable time when servicing the air conditioning on vehicles with large refrigerant volumes, such as buses and trains. Since downtime is extremely costly for operators, key service tasks such as refrigerant recovery, evacuation and refrigerant recharging need to be performed within a tight timeframe. The WAECO ASC 6400 G perfectly meets these requirements. Featuring a 192 l vacuum pump and an extra fluid pump, the fully automatic service unit guarantees fast and efficient refrigerant recharging. It can be upgraded with a heat belt to save a further 80 % work time. The ASC 6400 G optionally features the fresh oil and UV additive feeding system. It allows moisture-free and clean storage of refrigerant oils even over longer periods of time and therefore cuts A/C service costs.

SPECIFICATIONS

| GENERAL | |

|

SKU number |

9103303106 |

|

For Refrigerant |

R1234yf, R134a, R513a |

|

Input voltage (AC) |

220-240 V |

|

Input frequency |

50/60 Hz |

| RECOVERY / RECYCLING | |

|

Purity of recovered refrigerant (SAE J 2099) |

Yes |

|

Refrigerant recovery rate |

30.00 kg/h |

|

Vacuum pump capacity |

192 Litre/Minute |

|

Performance of the hermetic compressor |

0.32 kW |

|

Dry filter capacity |

150.00 kg |

|

Refrigerant recycling rate |

Min. 95 % |

|

Can be used as diagnosis tool |

No |

| CHARGING | |

|

Refrigerant Capacity |

30.00 kg |

| PROCESSES | |

|

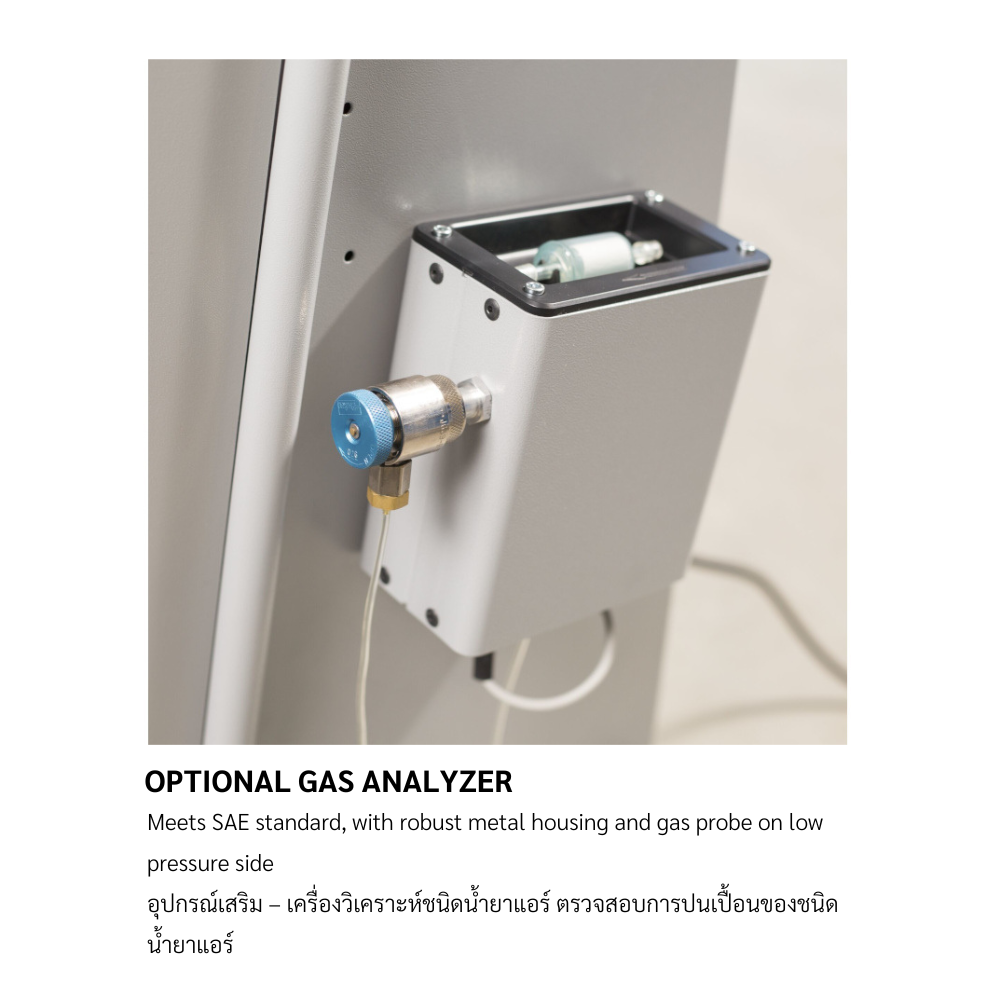

Refrigerant analysis |

Optional |

|

Recovery/recycling |

Automatic / Electronic |

|

Purging of non-condensable gases |

Automatic / Electronic |

|

Purging of used oil |

Automatic / Electronic |

|

Evacuation |

Automatic / Electronic |

|

Vacuum check |

Automatic / Electronic |

|

Nitrogen leak check |

No |

|

Injection of leak detection additive |

Automatic / Electronic |

|

Injection of oil into the A/C system |

Automatic / Electronic |

|

Refrigerant charging |

Automatic / Electronic |

| CONTROL PANEL | |

|

High/low pressure indicated by |

Manometer |

|

Vacuum indicated by |

Display |

|

Total process control indicated by |

Display |

|

Option to set the evacuation time |

Yes |

|

Protocol print-out possible |

Yes |

| DIMENSION | |

|

Depth x Height x Width |

560 x 1,300 x 650 mm. |

|

Net Weight |

110 Kg. |