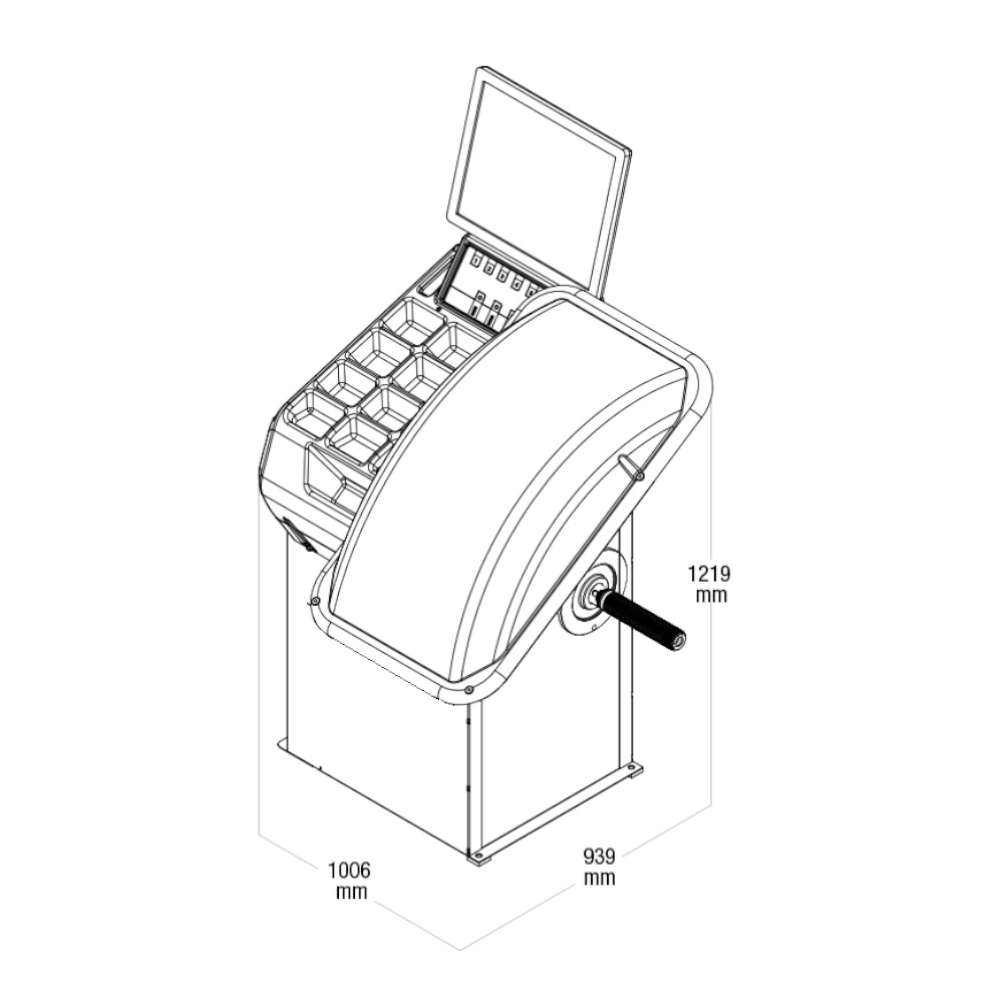

F395

Video space-saving 3D balancer

The compact wheel balancer with monitor and advanced innovative features: 3D wheel measurement with Virtual Sonar, AutoAdaptive mode and stationary brake

Detection of wheel data

The automatic gauge enables detection of distance and diameter from 12″ to 28″ with relative activation of desired balancing program (clip-on or stick-on weights). No error due to manual inputs possible.

The machine enables the operator to work according to his preferences. The correct application of counterweights can be selected in two different modes: with the accuracy of position repeater or the conventional 12 o’clock position.

Virtual Sonar

Virtual Sonar is the new software for a 3D wheel measurement which enables, in the absence of an actual sonar device, to detect the rim width. After having detected the first correction plane thanks to the automatic gauge, Virtual Sonar calculates the position of the external plane, according to the measured unbalance and the tolerance calculated with AutoAdaptive mode.

AutoAdaptive Mode

The innovative tolerance calculation system AutoAdaptive Mode is based on the evaluation of the residual imbalance limit value corresponding to an acceptable perceived vibration. For each wheel that is balanced, the software AutoAdaptive Mode detects weight and dimensions and calculates the tolerance value that will cancel any vibration perceived on the steering wheel. AutoAdaptive Mode grants the highest comfort when driving.

Electric brake

The electromagnetic brake, supplied as standard, locks the wheel in the exact weight position, granting a higher accuracy during correction.

Automatic Approach

Once the measuring launch is completed, thanks to the Automatic Approach system, the wheel automatically stops around 15° from the exact point of application of the counterweight, allowing the operator to position it correctly with a little movement.

Programs: ALU S – SPLIT – OPTIMIZATION

F395 features all the latest programs for unbalance correction. Unlimited correction modes for stick-on weights (ALU S), hidden weights behind the spokes (SPLIT) and matching (UNBALANCE OPTIMIZATION).

Heavy-Duty

The entire range of FOCUS balancers is manufactured to the strict high standards imposed by the company. Heavy duty batch balancing use doesn’t hamper even the smallest of FOCUS balancers. Thanks to this sturdiness, the choice of an appropriate model is not subject to intensity of use but only to service requested. Each model differs from the other in levels of process automation and analysis capability effect on wheel.

Wheel guard

Machine supplied with a space-saving wheelguard. Protects operator and ambient from mud and water sprays.

The spin cycle starts by simply lowering the wheel guard.

| Single phase power supply | 115 / 230 V 50 / 60 Hz |

| Max. absorbed power | 0,8 kW |

| Balancing speed | 100 rpm |

| Measuring cycle for 15 kg (33 lb) wheel | 4.7 s |

| Measurement uncertainty | ±0,5 g |

| Resolution | 0,5 g |

| Average noise | < 70 dB (A) |

| Rim width setting range | 1.5” ÷ 20” or 40 ÷ 510 mm |

| Rim diameter setting range | 10” ÷ 30” or 265 ÷ 765 mm |

| Max wheel weight | < 75 kg |

| Machine weight | 110 kg |