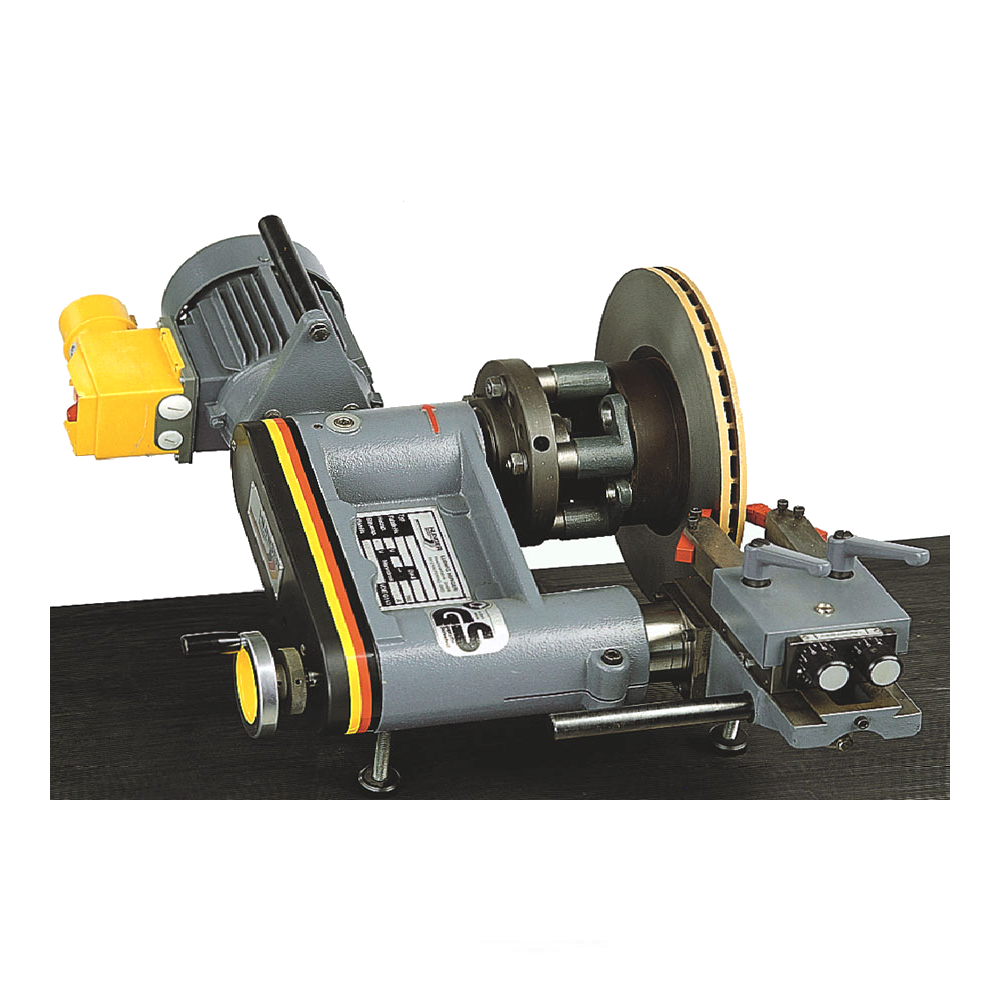

ON-CAR BRAKE SERVICING MACHINES HUNGER E326a

The standard on the car brake lathe ensures best braking performance without vibration problems and satisfied customer. In more than 4500 work shops around the world for over 25 years!

• Machining rotors on the car is the only method to precisely compensate for lateral runout in the hub and bearing, a major factor in eliminating customer comebacks through vibration problems from pedal pulsation and noise. In addition on-car machining saves also time where the removal of the disc from the hub is not easy (hubbed rotors).

• Easy operation and perfect results regarding surface finish, parallelism and lateral runout of the brake disc.

• Less warranty complaints = higher customer satisfaction and better reputation.

• Better braking performance through perfect seat and grip between pad and disc surface.

• Brake discs are machined on both sides in one operation.

• Intermittent feed for a non-directional finish eliminats noise complaints

• For dismounted brake discs as well as brake drums and for flywheels, the E 326a can also be used as a bench lathe.

• Approvals and recommendations by all major car manufacturers.

Technical Datas :

| Capacity : | |

| Max. brake disc diameter | 350 mm |

| Max. brake disc thickness | 38 mm |

| Slide travel radial axial | 100-115 mm |

| Spindle speed and feed : | |

| Spindle speed | 75 rpm |

| Feed (intermittent) | 0.10 mm/rev |

| Electrical equipment : | |

| Total connected load | 0.37 kW |

| Supply voltage | 230 V |

| Frequency | 50Hz |

| Power supply fuse rating | 16A |

| Type of enclosure | IP54 |

| Dimensions and weight : | |

| Space required with storage cabinet | 780 x 300 x 670 mm |

| Space required-Machine and working area | 1 x 1 m |

| Machine weight | 30 kg |

The noise level at full load measured in accordance with standard DIN EN 31201 at a distance of 1 m. form the machine surface in open space amounted to 70 dB(A).